Maintaining employee engagement is vital for any company’s success.

Unfortunately, employee engagement is low in the manufacturing industry. The 2020 employee engagement report by Workday shows employee engagement rates in manufacturing is one of the lowest across industries - at around 34%.

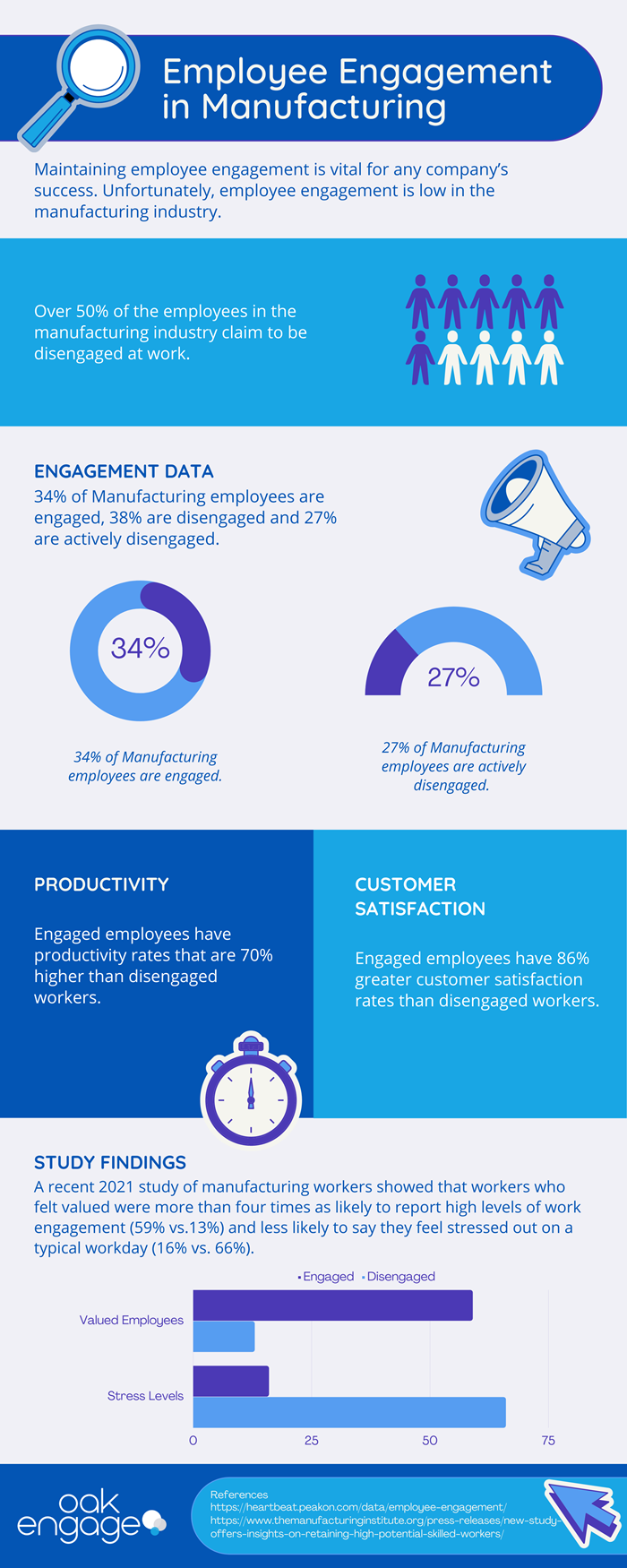

In other words, that’s over half of manufacturing employees claiming to be disengaged at work.

However, there are many ways to engage manufacturing employees and drive greater retention across the workforce. In this blog we’ll cover:

- What is employee engagement in manufacturing?

- Why is it important in the manufacturing industry?

- Reasons for poor employee engagement in manufacturing

- How to improve employee engagement in manufacturing

Key Takeaways

⭐️ Employee engagement rates in manufacturing are one of the lowest across industries.

⭐️ Many employees in manufacturing feel like they can’t enact change in their organisation.

⭐️ Not communicating in the right way is a widespread problem in manufacturing.

⭐️ A recent 2021 study of manufacturing workers showed that workers who felt valued were more than four times as likely to report high levels of work engagement.

Our goal is to give you tips and ideas that can spark your imagination and get you on the right track to building and improving engagement for your industrial teams and deskless workforce.

Let's get straight into it!

What Is Employee Engagement in Manufacturing?

It’s important to highlight that manufacturing work can be physically demanding. Employees are lifting, walking or standing all day or night, depending on their shift.

Of course, the pandemic didn't do the manufacturing industry any favours, in fact, it only contributed to the lack of engagement.

Communication became chaotic as shifts were constantly changing due to the strict rules. Employees were left waiting to know if they still had a job or for further job updates.

Employee engagement in manufacturing became an all time low.

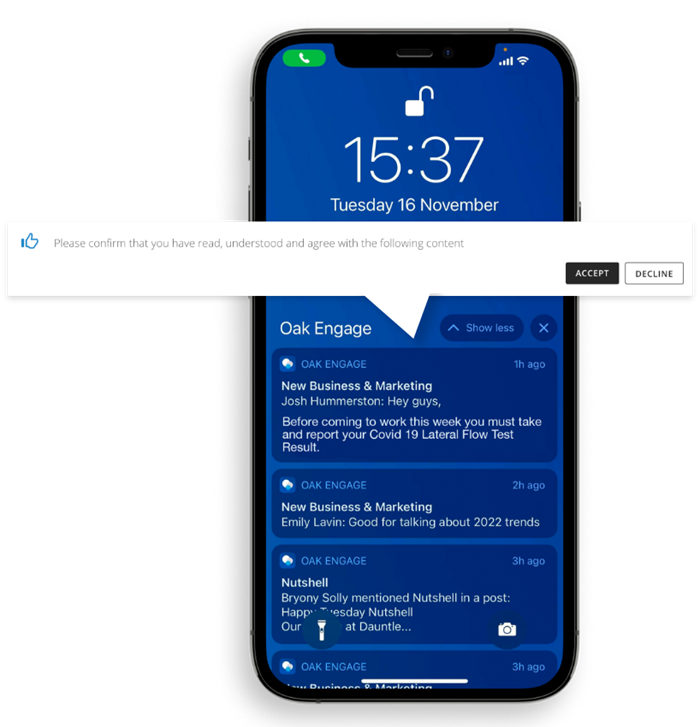

Once restrictions were eased and people went back to work, employees wanted that feeling of safety. However, outdated communication methods such as calls, texts, emails and paperwork made this unattainable.

With outdated communication comes low employee engagement.

Low engagement could cause employees to unwillingly break safety protocols, increasing the risk of incidents to themselves and those around them.

Why Is It Important in the Manufacturing Industry?

So, why is employee engagement so important in the manufacturing industry?

Executives and managers have unlimited choices for communicating with their employees, but they don't always take advantage of those choices or opportunities to their full potential to create an engaged workforce.

When employees are disengaged, it leads to lost sales, lost production, low productivity and high turnover rates.

How do we know this? Every year in the United States, $450-550 billion in losses is caused by disengaged employees.

Let’s just let that sink in for a moment.

On the other hand, engaged employees have productivity rates that are 70% higher than disengaged workers, according to a study from Manufacturing.

They also have a:

- 78% higher safety record

- 70% lower employee turnover

- 86% greater customer satisfaction

- 44% greater profitability

That is why achieving employee engagement is so important in the manufacturing industry.

Reasons for Poor Employee Engagement in Manufacturing

Now you know why employee engagement is important, let’s take a look at the reasons which cause poor engagement in manufacturing.

The leading causes of low employee engagement typically centre around a few key areas:

Lack of Data/Document Management Software

Many manufacturing companies must manage complex procedures that don’t exist in other industries.

Maintaining engagement requires extra effort to ensure safe processes and the ability to have meaningful conversations with union leaders.

If companies don't have a suitable data and document management process in place, information can become lost across the organisation, causing low engagement.

With this in mind they will likely have a big emphasis on training documentation, onboarding information and safety policies which will all need to be stored in a central location. There's also a disconnect between manufacturers and up to date, modern technology.

With a shortage of those skilled in IT software, it's important that they have simple, easy to use intranets at their disposal.

Data protection is important for manufacturers - with a slow uptake in technology however, there's a significant gap in efficient and secure data management - leaving software like Oak as the ideal solution.

Outdated Methods of Communication

Not communicating in the right way is a widespread problem in manufacturing.

A large proportion of employees will be working on the factory floor, meaning that they represent a large deskless majority within their workforce.

They will also work a lot with logistics, distribution, buyers etc. so they will need to have a robust extranet in place to deal with all the external collaboration, which a lot of companies don’t have.

Additionally, manufacturers are managing multiple generations in one workforce, and each has its own unique way of communicating.

If you don’t reach everyone with a common communication tool or platform, you risk alienating employees.

Lack of Feedback/Not Listening to Employees

Many employees in manufacturing feel like they can’t enact change in their organisation and their voices aren't being heard.

Management should be conducting company surveys regularly and acting on their employees feedback.

How to Improve Employee Engagement in Manufacturing

⭐️ Streamline Communication Channels

Communication should be simple. Especially for frontline workers.

Working in manufacturing, priorities will predominantly lie with organisation, extranet, process and procedure. It’s important to see if there are ways to streamline your communications channels to make it easier for your workers.

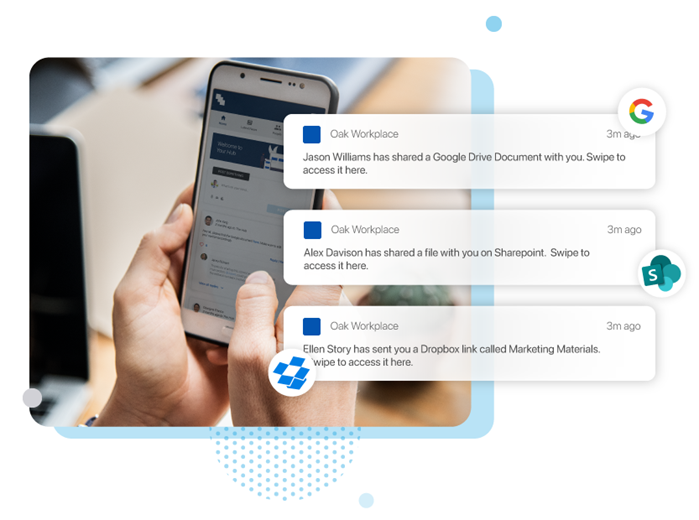

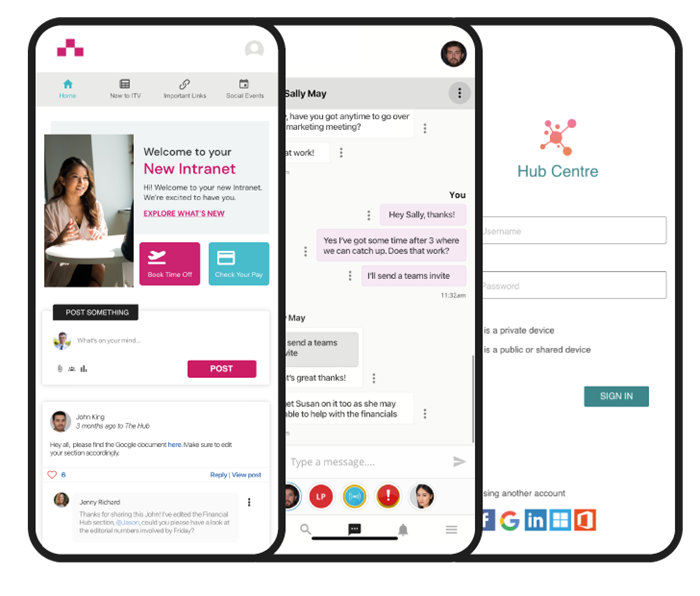

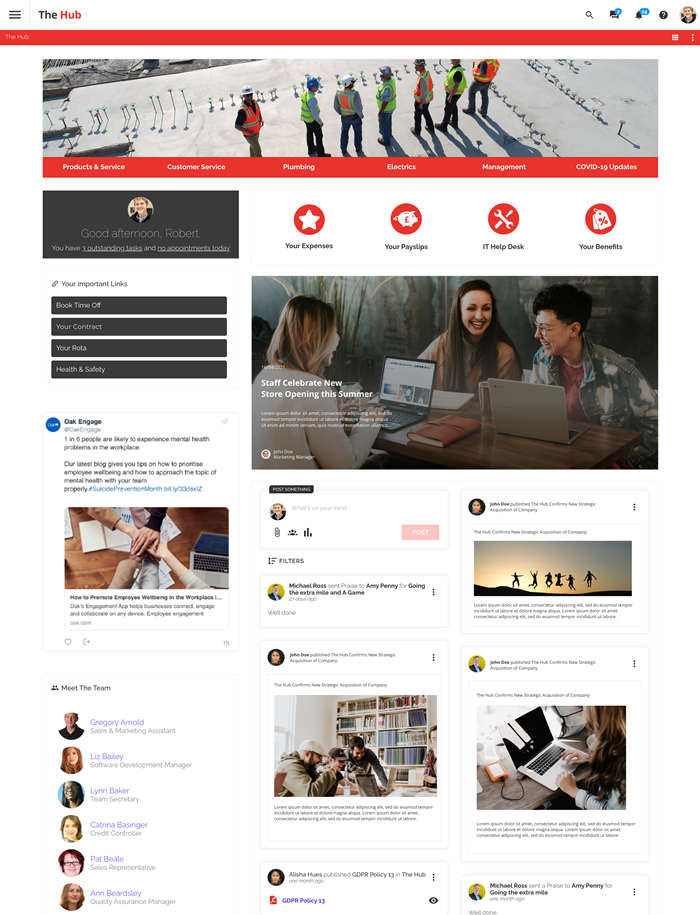

Implementing a company intranet allows deskless employees to access everything they need in one place.

So how can this be achieved?

At Oak, we know how important efficiency and connectivity are within the manufacturing profession. We empower organisations to improve communication, boost connectivity and centralise information.

We support large organisations and deskless employees, regardless of shift pattern.

The solution is always on hand to support teams at any time, anywhere.

Working shifts in manufacturing can be an emotionally challenging and stressful working environment. That’s why it's important to create a centralised space for employees to connect.

Oak is designed to facilitate a more streamlined operation within any industry.

In manufacturing, this helps to adapt to a more modern and holistic undertaking of day to day operations.

Recommended Reading 📖: Business Communication: The Complete Guide

⭐️ Recognise & Appreciate Your Employees

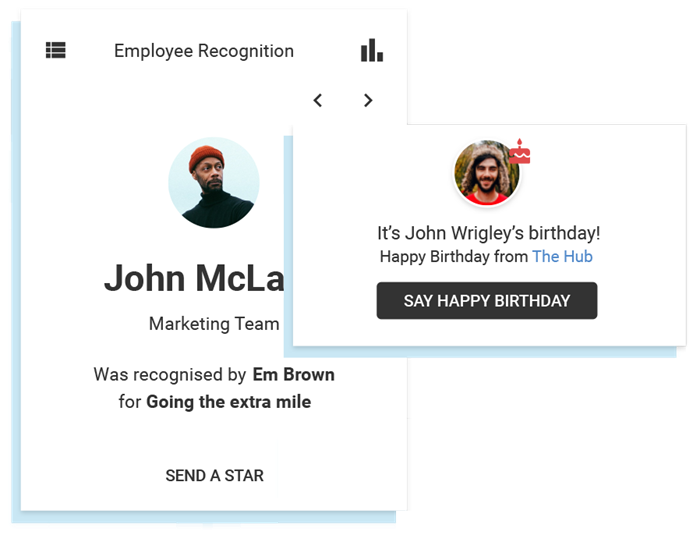

Recognition in the workplace is a vital contributor to employee engagement and happiness.

A recent 2021 study of manufacturing workers showed that workers who felt valued were more than four times as likely to report high levels of work engagement (59% vs.13%) and less likely to say they feel stressed out on a typical workday (16% vs. 66%).

In short, workers don’t want to be taken for granted.

Employees want to feel as if they’re bringing something to the table and benefiting their organisation in some way.

Many solutions are available to support recognition in the workplace, here are just a few to get you thinking:

- Implementing a company intranet

- Implementing a peer-to-peer recognition platform

- Taking 5 minutes at the end of a team meeting to give shout-outs.

- Sending a recognition message on your company intranet

- Providing regular and spontaneous verbal recognition

Recommended Reading 📖: Employee Recognition In The Workplace (Complete Guide)

⭐️ Give Employees a Voice

Research suggests that a key indicator of organisational success is a company’s ability to make their employees feel heard.

Giving employees a voice is a critical component of establishing a workforce that is happy, more productive and engaged.

However, employees must be convinced that their suggestions play an integral role in decision making. They will then become willing to communicate ideas, concerns and opinions within their role.

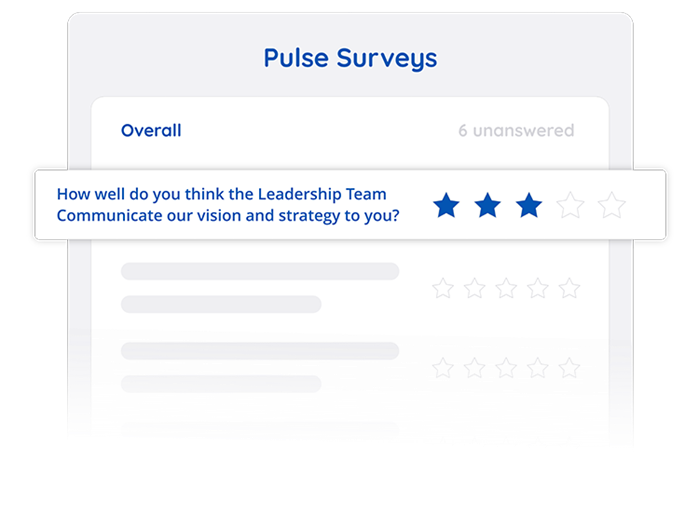

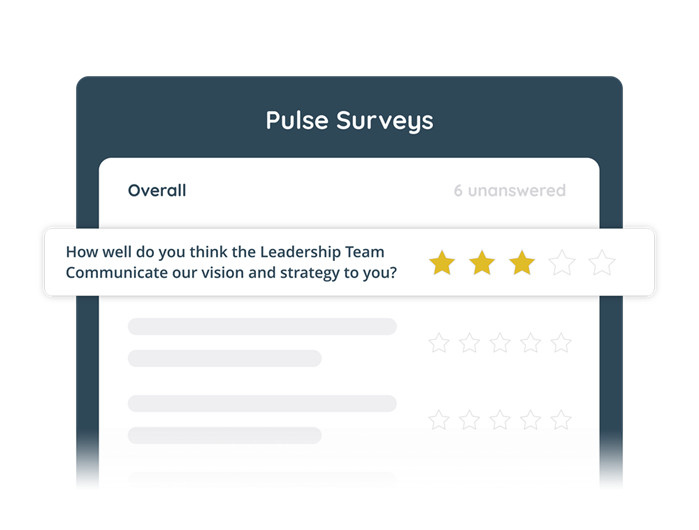

You can understand your employees requirements with pulse surveys and polls.

That means no more gathering information via emails. You can create and launch a poll or pulse survey with ease for better engagement rates within your company. All in a matter of minutes.

Recommended Reading 📖: Employee Voice in the Workplace (Ultimate Guide)

⭐️ Implement Career or Learning Developments

More often than not, engagement issues stem from a lack of education about the field or lack of knowledge about the product.

Providing opportunities for workers to learn why their work matters to consumers can boost motivation.

Why not set up opportunities for virtual factory tours and video snippets highlighting both employees and customers. It’s also always interesting for consumers to see how products are made and workers can learn why company products matter.

But your question might be, how can I do this?

It’s inefficient for managers to communicate every piece of information to their teams, especially by email. This will cause information overload and employees will more than likely be overwhelmed and forget important information.

In reality, their time is often better spent mentoring their direct reports and helping them grow. Leaders can do this by walking the floor, learning about effective practices, exploring potential improvements, and offering feedback.

You can also offer employees a digital workplace allowing them to access training videos, guides, and how-tos at any time.

⭐️ Treat Employees with Respect & Promote Inclusivity

Disengagement can often stem from perceived unfairness.

For example, employees may believe that others are receiving better benefits or perks than them. Or that they are being excluded based on their role of function within the organisation.

This type of disengagement is easy to avoid.

Make sure that your manufacturing employees are receiving the same treatment and perks as everyone else. Doing so will demonstrate value and respect for them.

If you’re looking for ways to boost your employee experience in the manufacturing industry, reach out for a demo of our platform. Let’s see how we can help to bolster your engagement and retention stats through the use of modern workplace technology.